Case

grinding in pper mines

2022-12-23T14:12:24+00:00

Copper Concentrator Autogenous Grinding Practices at Mount

1 Copper Concentrator, 2 Metallurgical Development, Mount Isa Mines Limited, 3 Julius Kruttschnitt Mineral Research Centre, Brisbane, Australia ABSTRACT In the copper concentrator, a traditional crushing and primary grinding circuit was replaced by two autogenous grinding mills (98m diameter x 44m length) in June 1991There is always the odd job, or rework that requires manual grinding of copper One of the main reasons copper is avoided is because it is difficult to grind and it requires additional handwork after machining This is due to the annoying burrs thrown up by machining, whether by milling or grinding Flood coolant is a great way to avoid the burrs, however, most manual surface grinding Solving The Mystery Of How To How To Grind CopperThe copper concentrator was rebuilt in 1973, with rod and ball milling and threestage flotation, to supply the roaster and conventional blister copper smelter on site In 1981, Mount Isa commenced anode casting as well In 19881989, two 64MW AG/SAG grinding mills replaced the Mount Isa Copper Mine, Queensland, Australia

Make your copper mine more efficient and

With declining ore grades, you need to dig deeper and into harder rock to increase production at your copper mine This requires reliable and wearresistant equipment A focus on water management is a must to control costs and obtain your license to operate We discover solutions that increase sustainable productivity at your mine27/5/2020 Wichita Clutch Grinding Mill Clutch for Copper Mine SAG MillFull Article: https://altramotion/newsroom/2016/12/apgrindingmillclutchforcopperminWichita Clutch Grinding Mill Clutch for Copper Mine SAG 21/3/2019 Using autogenous and semiautogenous grinding and flotation methods, the Highland Valley Copper Mine is the largest openpit facility of its kind in Canada (and one of the largest in the world)Top 10 active copper mines in Canada Mining Energy

Pathways towards zeroemission copper mines

28/6/2020 “In general, the energy consumption in the primary copper process is dominated by the earlier stages of beneficiation This is due to the high energy demand requirement Even though the vast majority of copper EDM electrodes for injection mold making are machined by machines, knowing how to grind copper is a valuable skill in the surface grinding process There is always the odd job, or rework that requires manual Solving The Mystery Of How To How To Grind Copper1 Copper Concentrator, 2 Metallurgical Development, Mount Isa Mines Limited, 3 Julius Kruttschnitt Mineral Research Centre, Brisbane, Australia ABSTRACT In the copper concentrator, a traditional crushing and primary grinding circuit was replaced by two autogenous grinding mills (98m diameter x 44m length) in June 1991Copper Concentrator Autogenous Grinding Practices at Mount

Mining Process For Copper – Series IIxinhai

The second stage is grinding and flotation process Due to a different distribution of fine particle size of useful and gangue minerals in copper mining process plant, and the ore is easily argillization Therefore, separating copper usually adopts grinding and flotation processIn the Aitik copper mine a raised specific charge from 09 to 13 kg/m 3 gave rise to an increase in the throughput by nearly 7% due to more fines produced and shorter grinding time achieved Similarly, a high specific charge from 2 to 30 kg/m 3 resulted in an increase in the mill throughput by 20–40% View chapter Purchase bookCopper Mines an overview ScienceDirect Topicsgrinding media) In 1977, the primary copper industry purchased 121trillion Btu of energy, or around 85 miIlion Btu per short ton of cathode copper produced ] This compares to around 15 million Btu/ton for iron mining and steel production, 24 million Btu/ton for lead production, and 64 million Btu/ton for zinc, Mining uses about 20 percent of the total energy requirement; milling around 40 Chapter 7 Energy Use in the Copper Industry

ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

grinding is one such process employed at several mining operations in Australia including Mount Isa Mines Limited in Australia Mount Isa Mines is a business unit of MIM Holdings Limited MIM is an Australianbased international mining and mineral processing company with around 8000 employees worldwide Major products include copper, gold, zinc In this process copper ore is mined, crushed, ground, concentrated, smelted and refined The mining, crushing and grinding portions of the processing are extremely energy intensive since the rock must be reduced essentially to talcum powder fineness in order to separate the copperbearing minerals from itHow Hydrometallurgy and the SX/EW Process Made Copper 23/11/2016 About 80% of global copper mine production comes sulphide ores that ore processed using grinding and flotation plants to produce concentrates for smelting The rest comes from mines using dump or heap leaching, solvent extraction and electrowinning to produce cathode copper Most copper mines are large, low grade, open pitsWhat drives GHG emissions from copper production

receives major grinding solution order Mining

Each of the four lines will consist of a single 40ft (122m) semiautogenous grinding (SAG) mill with a 28MW drive and two 28ft (85m) ball mills, each with a 22MW drive When installed, the SAG mills will be the largest in all of Asia All drives are gearless motor drives from ABBThe initial intent for Murrawombie, was for it to be a satellite mine for the Tritton Copper Operations, supporting the main Tritton underground mine and providing topup feed to the central processing plant Having multiple mines in production reduces the variation in feed supply to the processing plant, which enables operational optimisation Murrawombie has become a highgrade producer in Tritton Underground Aeris ResourcesEven though the vast majority of copper EDM electrodes for injection mold making are machined by machines, knowing how to grind copper is a valuable skill in the surface grinding process There is always the odd job, or rework that requires manual Solving The Mystery Of How To How To Grind Copper

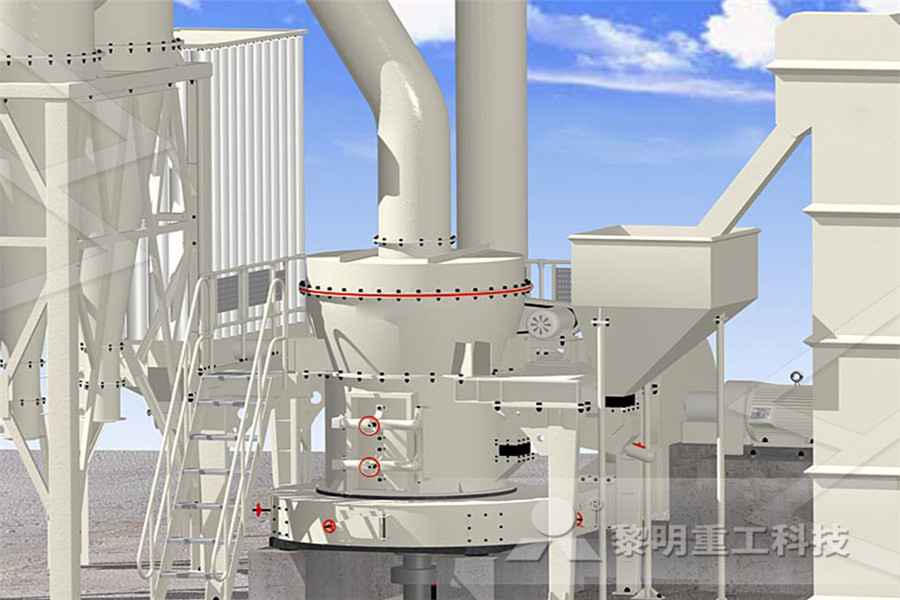

Equipment Of Copper Ore Grinding osteopathieherentbe

Copper ore is definitely an ore that may produce copper metal by crushing in ore crushing plant grinding in Ball mill and smelting in the furnace and also a bit of tin ore Machinery can be a proessional manufacturer of copper ore grinding equipment and crushing equipment Copper Ore Crushing and Grinding Process"grinding media) In 1977, the primary copper industry purchased 121trillion Btu of energy, or around 85 miIlion Btu per short ton of cathode copper produced ] This compares to around 15 million Btu/ton for iron mining and steel production, 24 million Btu/ton for lead production, and 64 million Btu/ton for zinc, Mining uses about 20 percent of the total energy requirement; milling around 40 Chapter 7 Energy Use in the Copper IndustryIn this process copper ore is mined, crushed, ground, concentrated, smelted and refined The mining, crushing and grinding portions of the processing are extremely energy intensive since the rock must be reduced essentially to talcum powder fineness in order to separate the copperbearing minerals from itHow Hydrometallurgy and the SX/EW Process Made Copper

regrinding mill flow sheet vertimill copper mine

Grinding Mill Chin; copper benification copper mine turn key operation copper mine turn key operatio simple flow sheet in a copper mine Coal If you need more information about simple flow sheet in a copper mine, copper, copper mine mill is a key equipment for regrinding copper mine grinding mill nifftEach of the four lines will consist of a single 40ft (122m) semiautogenous grinding (SAG) mill with a 28MW drive and two 28ft (85m) ball mills, each with a 22MW drive When installed, the SAG mills will be the largest in all of Asia All drives are gearless motor drives from ABB receives major grinding solution order Mining Murrawombie is the secondary production source for the Tritton Copper Operations Production at commercial rates was achieved in 2018 and was increased in 2019 to 470,000 tonnes The mining methods employed at Murrawombie are either small open stopes, or bench stopes, with a combination of cemented and dry rock backfillTritton Underground Aeris Resources

Major Mines Projects Lubambe Mine

Crushing and Grinding Processing Flotation; Flow Sheet: Summary: Lubambe Copper Mine has Plant infrastructure consisting of a concentrator plant, a laboratory and underground infrastructure; The concentrator incorporates crushing, milling, flotation and filtration The design capacity is 25 MTPA of ore at an average mill grade of 23% copper, yielding 45,000 tonnes of contained copper in For most Mining companies globally, work is grinding to a halt and operations at mines are being temporarily suspended as majors and minors move to enact measures to protect against the spread of Covid19 With governments from Africa to Latin America issuing lockdown orders, unprecedented disruptions to operations and supply chains are threatening the outlook for industrial and precious Mining operations grinding to a halt globally Mining In 1991, two semiautogenous grinding mills ("SAG mills") were installed in the copper concentrator This freed up two ball mills that were transferred to the No 2 concentrator to Mount Isa Mines Wikipedia