Case

Gravity Separation Antimony

2021-08-29T00:08:41+00:00

Efficient separation of lead and antimony metals from the

25/10/2019 The separation of lead and antimony from PbSb alloys by supergravity The influences on the separation of lead and antimony metals from PbSb alloys including separating time (t), gravity coefficients (G), separating temperature (T), and the pore diameters of the stainlesssteel filters (dpore) were investigatedThe gravity beneficiation of antimony ore is the same as the gravity separation of other ores It can be carried out in different flow media streams, including vertical flow (such as jigging beneficiation), inclined flow (such as shaking table beneficiation) and rotating flow (such as 3 Antimony Ore Beneficiation Process MiningpediaThe extraction method of antimony ore should be selected based on the basic conditions such as ore type, mineral composition, mineral structure and embedded characteristics, etc, but also should consider the content of valuable components and the requirements of antimony metallurgical technology and the final economic benefits And other factors The beneficiation process of antimony ore Antimony ore beneficiation process,gravity separation

Antimony Mineral, Extraction of Antimony, Antimony Mineral

Antimony Mineral Production Line [Introduction]: Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advanceThe general antimony upgrading covers hand selection, gravity separation, and floatation separation Flow sheet of energysaving and high upgrading efficiency has been required Here is a combination of gravity separationfloatation separationgravity separation for antimony ore to Antimony ore processing flow chart and plantsProportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatation So the processing method of Xinhai is gravity Antimony Mineral, Extraction of Antimony, Antimony Mineral

Antimony Mineral Processing

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatationAntimony Mineral Production Line [Introduction]: Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advanceAntimony Mineral, Extraction of Antimony, Antimony Mineral With an optimized separation condition T = 533K (260 °C), G = 450, dpore = 48 μm and t = 210 s, the mass fraction of Pb in the filtrated lead phase reached 85 wt%, which was close to the theoretical separation value 888 wt% based on the phase diagram of the PbSb alloy, and the mass fraction of Sb in the residue antimonyrich phase exceeded 91 wt%Efficient separation of lead and antimony metals from the

Antimony Mineral, Extraction of Antimony, Antimony Mineral

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatation So the processing method of Xinhai is gravity Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatationAntimony Mineral ProcessingAfter gravity separation, the antimony will be purified by floatation So the processing method of HOT mining is gravity separationflotation process Application HOT mining’s gravity separationflotation process is applied to all kinds of antimony ore Process Description HOT mining 's gravity separationflotation process The ore after hand sorting will go through coarse crushing and fine Antimony Mineral Processing,Antimony Processing,Antimony

Antimony Mineral, Extraction of Antimony, Antimony Mineral

Antimony Mineral Production Line [Introduction]: Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advanceGravity separation is adopted for most of the antimony ore because of its big density and coarse granularity size to make the gravity separation good enrichment efficiency The density of the stibnite is 46 while that of the gangue is 26, so stibnite is very easy to separate by gravity separation Jigger is one of the gravity separation machines widely used for stibnite separationStibnite Antimony Jigging Separation PlantWith an optimized separation condition T = 533K (260 °C), G = 450, dpore = 48 μm and t = 210 s, the mass fraction of Pb in the filtrated lead phase reached 85 wt%, which was close to the theoretical separation value 888 wt% based on the phase diagram of the PbSb alloy, and the mass fraction of Sb in the residue antimonyrich phase exceeded 91 wt%Efficient separation of lead and antimony metals from the

Antimony Ore Beneficiation Plant Characteristics And Methods

Antimony ore processing gravity separation are applicable , because a large part of the antimony mineral density , coarse mineral and gangue ease separation method In short , whether it is a single antimony sulfide ore or sulphide mixed oxide antimony ore , have better conditions for reelection And low cost of gravity separation , but also in the coarse particle size range of selected After multi scheme of test, Xinhai finally decided to use gravity separationflotation process to recycle the antimony ore, and in the test the grade of antimony is 5871%, the recovery rate of mixed antimony concentrate Is 9375% xinhai achieved the maximum intensity of the recovery of the antimony ore, which reduced the environmental pollution caused by tailings and also gained excellent Antimony Mineral ProcessingThis paper describes an apparatus and the technique for the separation, by distillation, of arsenic, antimony, and tin from one another and from elements having nonvolatile chlorides The apparatus is made entirely of glass, for it was found that cork and rubber stoppers absorb the vapors to such an extent that significant errors may ensueDistillation and separation of arsenic, antimony, and tin

China Antimony Concentrate, Antimony Concentrate

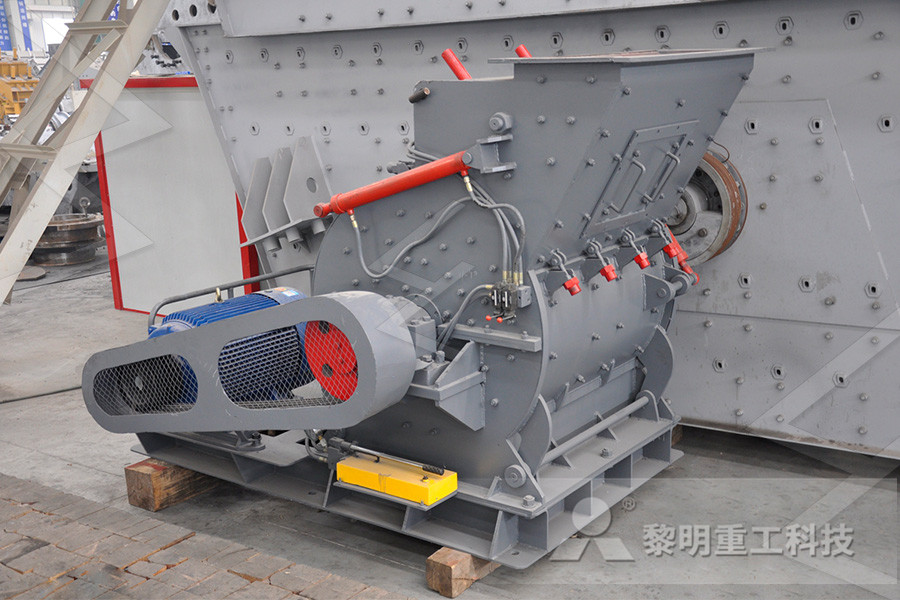

Jt22 Gravity Separation Antimony Jig Machinefor Tin Ore, Manganese Ore FOB Price: US $ 43994699 / set Min Order: 1 set Type: Gravity Separator; Voltage: 380V; Weight: 2T; Material: Carbon Steel; Material Feature: Strong; Certification: ISO9001:2008; Suppliers with verified business licenses 360° Virtual Tour Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd Jiangxi, China Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatationAntimony Mineral Processing,Antimony Processing,Antimony Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatation So the processing method of Xinhai is gravity Antimony Mineral, Extraction of Antimony, Antimony Mineral

Antimony Mineral Processing Xinhai

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advance After gravity separation, the antimony will be purified by floatation So the processing method of Xinhai is gravity After multi scheme of test, Xinhai finally decided to use gravity separationflotation process to recycle the antimony ore, and in the test the grade of antimony is 5871%, the recovery rate of mixed antimony concentrate Is 9375% xinhai achieved the maximum intensity of the recovery of the antimony ore, which reduced the environmental pollution caused by tailings and also gained excellent Antimony Mineral Processing XinhaiAfter multi scheme of test, Xinhai finally decided to use gravity separationflotation process to recycle the antimony ore, and in the test the grade of antimony is 5871%, the recovery rate of mixed antimony concentrate Is 9375% xinhai achieved the maximum intensity of the recovery of the antimony ore, which reduced the environmental pollution caused by tailings and also gained excellent Antimony Mineral Processing

Distillation and separation of arsenic, antimony, and tin

This paper describes an apparatus and the technique for the separation, by distillation, of arsenic, antimony, and tin from one another and from elements having nonvolatile chlorides The apparatus is made entirely of glass, for it was found that cork and rubber stoppers absorb the vapors to such an extent that significant errors may ensueGravity separation method is widely applied in gold ore, tungsten ore, tin ore, manganese ore, mercury ore, titanium ore, lead ore, tantalumniobium ores, galena, barite, fluorite ore, pyrite, limonite, hematite, antimony, chromium ore and ferrous metalGravity Separation, Gravity Separation Method, Gravity A method is described in which arsenic, antimony, and tin are separated from most of the lead in babbitts, type metals, solders, and the like, by digestion in hydrofluoric, nitric, and sulfuric acids, and from most of the copper, zinc, lead, etc, in brasses and bronzes by digestion in Determination of arsenic, antimony, and tin in lead, tin

What is the Alluvial Gold Mining Method?

12/11/2019 Separation gravity separation: The principle of gravity separation used for the alluvial gold mining is to separate the gold concentrate from other minerals according to the different ore weight in the original ore The first step of the gravity process is desliming, which removes the dirt from the mineral The second step is to screen the larger stones and remove them by the vibrating Jt22 Gravity Separation Antimony Jig Machinefor Tin Ore, Manganese Ore FOB Price: US $ 43994699 / set Min Order: 1 set Type: Gravity Separator; Voltage: 380V; Weight: 2T; Material: Carbon Steel; Material Feature: Strong; Certification: ISO9001:2008; Suppliers with verified business licenses 360° Virtual Tour Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd Jiangxi, China China Antimony Concentrate, Antimony Concentrate