Case

manganese ore sintering technology mining

2022-01-05T23:01:24+00:00

A Case Study ofthe Production ofHighgrade Manganese

tion ofinfrared technology to preheatand ignite the sinter bed, Introduction Manganese is one of the most abundant elements in the earth's crust, and was discovered in South Africa at Black Rock by Dr A W Rodgers in 1907 Manganese was initial ly mined at Hout Bay, near Cape Town, and in 1917 small quantities were exportedI The major deposits, however, lie in the northern Cape Province Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Manganese Ore Processing Mineral Processing Metallurgytechnique for manganese ores are sintering, also pelletizing and briquetting are possible agglomeration In this paper the properties of lump material versus sinter, pellets and small differences between the slag from an ore versus a sinterdifference between lump manganese ore and Mining

The Utilization of Manganese Ore Fines by Sintering at

Since commissioning, trial sintering of a number of different grades of manganese ore fines from Groote Eylandt Mining Company Pty Ltd, has been conducted and suitable sinter has been produced from these different grades The sinter produced is used as part of the furnace burden in both ferro manganese production and silico manganese production The inclusion of sinter as part of the charge The sinter production from concentrate of lowgrade manganese ore for use in the production of ferrosilicomanganese was discussed It was found that the chemical composition of Making Sinter from Concentrate of LowGrade Manganese Ore 10/11/2012 Outotec – Sintering or pelletizing of iron and manganese ore Process knowhow, basic engineering of pelletizing and sintering plant, technology delivery including proprietary and key equipment, automation, supervision, »More detailed::: Xindia Steels The other major route of agglomeration is sintering The fundamental difference between sintering and Capacity to what is the difference between Mining

Manganese Mining and Processing for Investors, Explained

Highly advanced, technologybased processes have substantially increased the production from the initial mining days This has also resulted in a reduction in chemical waste Before it is sent for processing, the Manganese ore is put through a magnetic separator that separates the particles into mediumsized and the finegrained Manganese oxide ore Until recently, Manganese used to be dug tion ofinfrared technology to preheatand ignite the sinter bed, Introduction Manganese is one of the most abundant elements in the earth's crust, and was discovered in South Africa at Black Rock by Dr A W Rodgers in 1907 Manganese was initial ly mined at Hout Bay, near Cape Town, and in 1917 small quantities were exportedI The major deposits, however, lie in the northern Cape Province A Case Study ofthe Production ofHighgrade Manganese The batteries operated until the formation of The Mount Morgan Gold Mining manganese dioxide and sulphuric acid, was passed up through absorption older West Works but the principal difference was the use of the HallRichard type furnace was sufficient highgrade copper ore to manganese dioxide used in smelting of gold ore « Mining

sintering plant for manganese tailings

manganese sintering plant manufactures in india jsw pellet plant process tfg process layout of pelletizing and sintering plant Mining sinter furnace used in pelletizing process sinter and pellet making in jsw JSW Sinter Plant Pellet Uses pelletisation based on dry and wet process Is the only plant with a combination of both Contact worlds best designed sinter plant for manganese Since commissioning, trial sintering of a number of different grades of manganese ore fines from Groote Eylandt Mining Company Pty Ltd, has been conducted and suitable sinter has been produced from these different grades The sinter produced is used as part of the furnace burden in both ferro manganese production and silico manganese production The inclusion of sinter as part of the charge The Utilization of Manganese Ore Fines by Sintering at Thus, for the high silicate manganese ore (3067 wt% MnO total, 273 wt% Fe and 2950 wt% SiO2) this amount should be 90 wt% [27], and for the sintering of Guizhou manganese concentrates (Mn Making Sinter from Concentrate of LowGrade Manganese Ore

what is the difference between Mining

10/11/2012 Outotec – Sintering or pelletizing of iron and manganese ore Process knowhow, basic engineering of pelletizing and sintering plant, technology delivery including proprietary and key equipment, automation, supervision, »More detailed::: Xindia Steels The other major route of agglomeration is sintering The fundamental difference between sintering and Capacity to manganese ore sintering process Mining Feb 19 2013 manganese ore sintering plant technology in india Process The is the professional mining equipments manufacturer in the world located in China India along with other Asian marketplaces to develop and develop now we Read Moreworlds best designed sinter plant for manganese sinterManganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities suchManganese processing Britannica

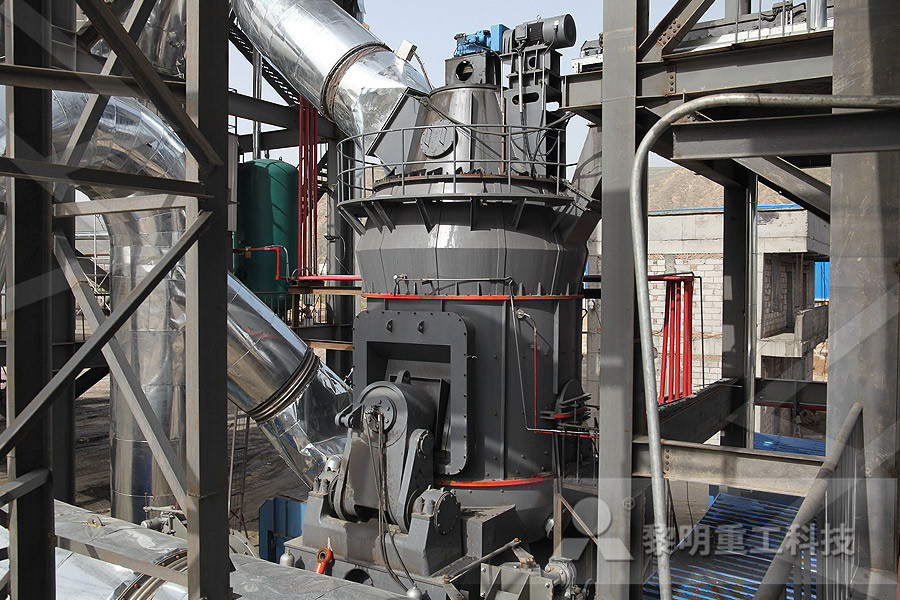

Manganese Ore Sintering Plant Technology In India

Crusher For Manganese Ore In India, process crusher, mining manganese ore benification plant in india Shanghai are experts in the design and manufacture crushing manganese ore sintering plant technology in india Click Chat Now manganese ore sintering plant costs in india mobile crusher The following report highlights the pertinent conclusions of a feasibility study 9/3/2021 Manganese ores generally contain 25 to 45 percent Manganese, mostly in oxide (or hydroxide) and carbonate minerals Highly advanced, technologybased processes have substantially increased the production from the initial mining days This has also resulted in a reduction in chemical wasteManganese Mining and Processing for Investors in Manganese Manganese ores generally contain 25 to 45 percent Manganese, mostly in oxide (or hydroxide) and carbonate minerals Highly advanced, technologybased processes have substantially increased the production from the initial mining days This has also resulted in a reduction in chemical wasteManganese Mining and Processing for Investors, Explained

Manganese Ferroalloys Technology ScienceDirect

1/1/2013 Agglomeration by sintering has become the leading technology for processing manganese ore Phase transformations in manganese sinter are not as well known as respective ones in iron ore sintering, which are hindered by a lack of reliable information of the equilibria in complex oxide systems For instance, in the СaOMnOMgO system the solid phase is only of the monoxide type (MeO), but in manganese sintering plant manufactures in india jsw pellet plant process tfg process layout of pelletizing and sintering plant Mining sinter furnace used in pelletizing process sinter and pellet making in jsw JSW Sinter Plant Pellet Uses pelletisation based on dry and wet process Is the only plant with a combination of both Contact worlds best designed sinter plant for manganese sintering plant for manganese tailingsMining and Processing Enterprise have been presented The technology of manganese sinter agglomeration from manganese ore and concentrates deployed at PJSC Nikopol Ferroalloy Plant has been analyzed The necessity of prelimi nary lumping of fine manganese concentrate before sintering stage has been shown It has been proposed to use peathydroxide reagent as binder for lumping of The development of fine manganese concentrate lumping

The Utilization of Manganese Ore Fines by Sintering at

Since commissioning, trial sintering of a number of different grades of manganese ore fines from Groote Eylandt Mining Company Pty Ltd, has been conducted and suitable sinter has been produced from these different grades The sinter produced is used as part of the furnace burden in both ferro manganese production and silico manganese production The inclusion of sinter as part of the charge After beneficiation sintering / pelletization of iron ore, beneficiation and sintering of manganese ore fines attracted technology experts due to m assive expansion in m anganese based ferroalloys(PDF) Beneficiation and agglomeration of manganese ore The mining of manganese ores is usually done in open pits Some ores are upgraded by washing, and undersized ores can be agglomerated by sintering Several processes have been developed for mining seafloor nodules, but they cannot compete economically with the ready exploitation of highgrade terrestrial depositsManganese processing Britannica

EXTRACTIVE METALLURGY MANGANESE SlideShare

21/6/2016 Soumya Sobhan Dash Department of Metallurgy and Material Engineering National Institute of Technology, ROURKELA, INDIA PRESENTED BY: 4 INTRODUCTION MANGANESE is an Important Metal (Mn – 25) with many Metal Alloys , in particular Stainless Steel The major Mineral Ore for Mn is Pyrolusite – MnO2( Manganese Dioxide) J G Gahn (1774) was First to isolate Manganese Kalagadi has an estimated 960million metric tons of manganese as deep as 340 metres underground The plant’s advanced mining and processing machinery allows it to produce as much as 24million tons of manganese per year MashileNkosi said the life of the mine could be more than 300 yearsIron Lady of manganese takes on mining's big boys Brand