Case

the process of operation of the parts of a jaw crusher

2021-03-09T04:03:42+00:00

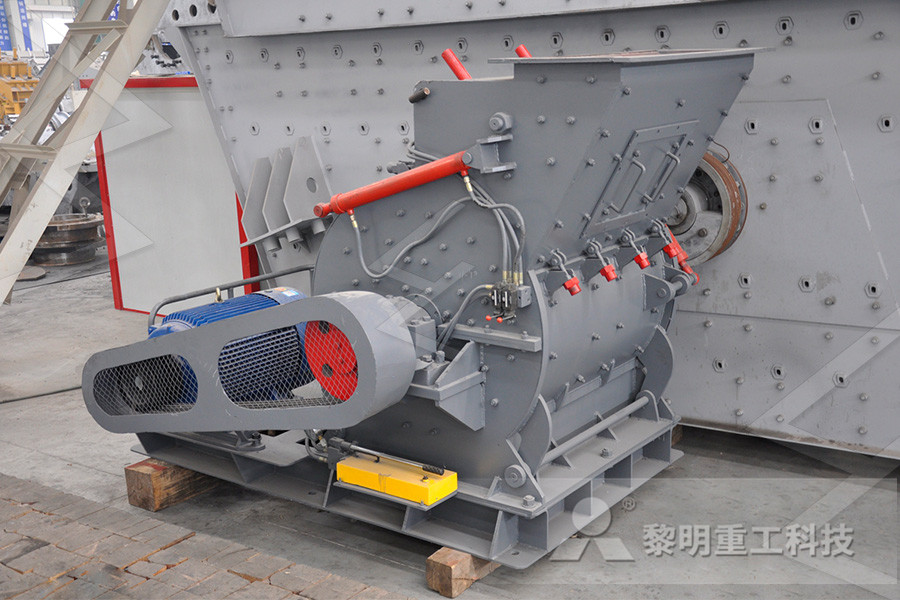

Analyzing the operation and design of a Jaw Crusher using

14/8/2019 The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machineStart according to the operation rules, that is, the startup sequence is the reverse production process; Lubricate the friction surface in time to ensure the normal operation of the jaw crusher and prolong the service life of the equipment 2 The grease used is general lithium grease or compound calcium grease, or the grease required by jaw crusher manufacturers 3 The grease added into 5 Tips Help you Operate Jaw Crusher Easily MCThe crushing process can be basically explained as a process where the materials are sandwiched between two jaw plates The movable jaw plates squeeze and crush the materials into several small pieces There are two main types of jaw crushers: double toggle and overhead eccentric jaw crusherThe Working Principle Of A Jaw Crusher Editors Top

The Working Principle of Jaw Crusher YouTube

1/4/2008 china This jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt andThe operation and maintenance of the fixed jaw crusher are very important while incorrect operation and maintenance or negligence in operation are often the main causes of accidents To improve the production and efficiency of the crushing process, we have to obey the rules of correct operation Here let’s take a look at the five aspects that should be noted in the crushing operation5 Keys to Teach You How to Correctly Operate Fixed Jaw 11/3/2021 Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw diesThe Most Practical Jaw Crusher Repair and Maintenance

Jaw Crusher Operation Guide JXSC Machine

Jaw crusher, as one of the modern crushing equipment, has a great crushing capacity and wide application Generally, working as a medium crusher, it is a standard crushing machine for the mining process and aggregate processing, quarry plant, etc The correct operation directly affects the jaw crusher working effect and service life The summary of correct operation matters needing attention Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or slightly upper camber) fixed in the front wall of the body, and the other is movable jaw plate (moving jaw), location inclined to form the next big small crushing chamber (working chamber) and the fixed jaw Jaw Crusher Working PrincipleJaw Crusher Working Principle gravelmillThe operation and maintenance of the fixed jaw crusher are very important while incorrect operation and maintenance or negligence in operation are often the main causes of accidents To improve the production and efficiency of the crushing process, we have to obey the rules of correct operation Here let’s take a look at the five aspects that should be noted in the crushing operation5 Keys to Teach You How to Correctly Operate Fixed Jaw

The Most Practical Jaw Crusher Repair and Maintenance

11/3/2021 a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service lifeThe relationship between the frequency of operation and capacity of the jaw crusher can be seen in Figure 45 This conclusion was substantiated in a more recent investigation of the power consumption in a size reduction process which is reported in three papers by Kwong et al (15), Adams et al (16) and Johnson etal (17) A sample of material was crushed by placing it in a cavity in a Jaw Crusher an overview ScienceDirect Topics1/8/2019 The operation procedure of cone crusher can be divided into four stages: before the start, at startup, at run time and turningoff time All conditions should be paid attention in each stage, and the potential problems can be found and solved timely and the service time can be prolongedCone Crusher Tips of Operation and Regular Maintenance

5 Common Questions about Jaw Crushers Answered For

30/5/2019 All jaw crushers reduce large sized rocks ore, or other materials by a compression action A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a Components Crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc Vibration Feeder: These machines feed the jaw and impact crusher with Crushing plant WikipediaThe operation of the crusher catches being struck by any reinforcing bar as it Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar) Struck by theHSE Quarries Safe operation and use of mobile jaw crushers

Six ways to take primary crushing underground Australian

1/8/2014 The heaviest part of a C200 jaw crusher for maintenance is the pitman assembly, which weighs approximately 40 tons and requires 5 meters of vertical space plus clearances for liftingJaw crusher, as one of the modern crushing equipment, has a great crushing capacity and wide application Generally, working as a medium crusher, it is a standard crushing machine for the mining process and aggregate processing, quarry plant, etc The correct operation directly affects the jaw crusher working effect and service life The summary of correct operation matters needing attention Jaw Crusher Operation Guide JXSC MachineA jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamber The movement of the swing jaw can be quite small, since Crusher Wikipedia

Jaw Crusher Working Principle gravelmill

Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or slightly upper camber) fixed in the front wall of the body, and the other is movable jaw plate (moving jaw), location inclined to form the next big small crushing chamber (working chamber) and the fixed jaw Jaw Crusher Working PrincipleThe main structure and parts replacement method of jaw crusher Feb 22, 2021 Jaw crusher has the characteristics of large crushing ratio, uniform particle size, simple structure, reliable work, easy maintenance, economical operation cost and so onWidely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industry and many other departmentsThe main structure and parts replacement method of jaw crusherThe main part of jaw crusher tilts during lifting process, the eccentric shaft is bent unilaterally 2 The hardness of crushed materials exceeds the specified standard, which cause the shaft breaking 3Breaking Reason of the Eccentric Shaft of Jaw Crusher

Crusher Jaws Low Fines Crushing Process Crusher Mills

Crushers, including jaw crusher,cone crusher, hammer crusher impact crusher, are part of our main Rock crusher plant price in India,Mobile stone jaw crusher Jaw crusher unique structure fully ensures high yielding and efficiency, low cost crushing process it produce fine particle size, Hammer Crusher Operation Crusher Mills, Cone Crusher, Jaw liming Crusher Low Fines 1/8/2019 The operation procedure of cone crusher can be divided into four stages: before the start, at startup, at run time and turningoff time All conditions should be paid attention in each stage, and the potential problems can be found and solved timely and the service time can be prolongedCone Crusher Tips of Operation and Regular Maintenance Figure 7 Tertiary Process Diagram 41 Figure 8 Jaw Crusher Cross sectional Assemblies 48 Table 1 Existing approved hours of operation 32 Table 2 Noise limits for the Ormeau Quarry 33 Table 3 Air quality limits for the Ormeau Quarry 34 Table 4 Primary and Secondary System definition 37 Table 5 Tertiary System definition 41 Table 6 Jaw Crusher Cross parts sheet 48 Table 7 Jaques Cone Crusher UNIVERSITY OF SOUTHERN QUEENSLAND

Six ways to take primary crushing underground Australian

1/8/2014 The heaviest part of a C200 jaw crusher for maintenance is the pitman assembly, which weighs approximately 40 tons and requires 5 meters of vertical space plus clearances for liftingThe crushing mode of the jaw crusher is a curved extrusion type Its main working part is two jaw plates, fixed jaw plate (fixed jaw) and movable jaw plate (movable jaw) Difference Between Jaw Crusher and Gyratory Crusher JXSC